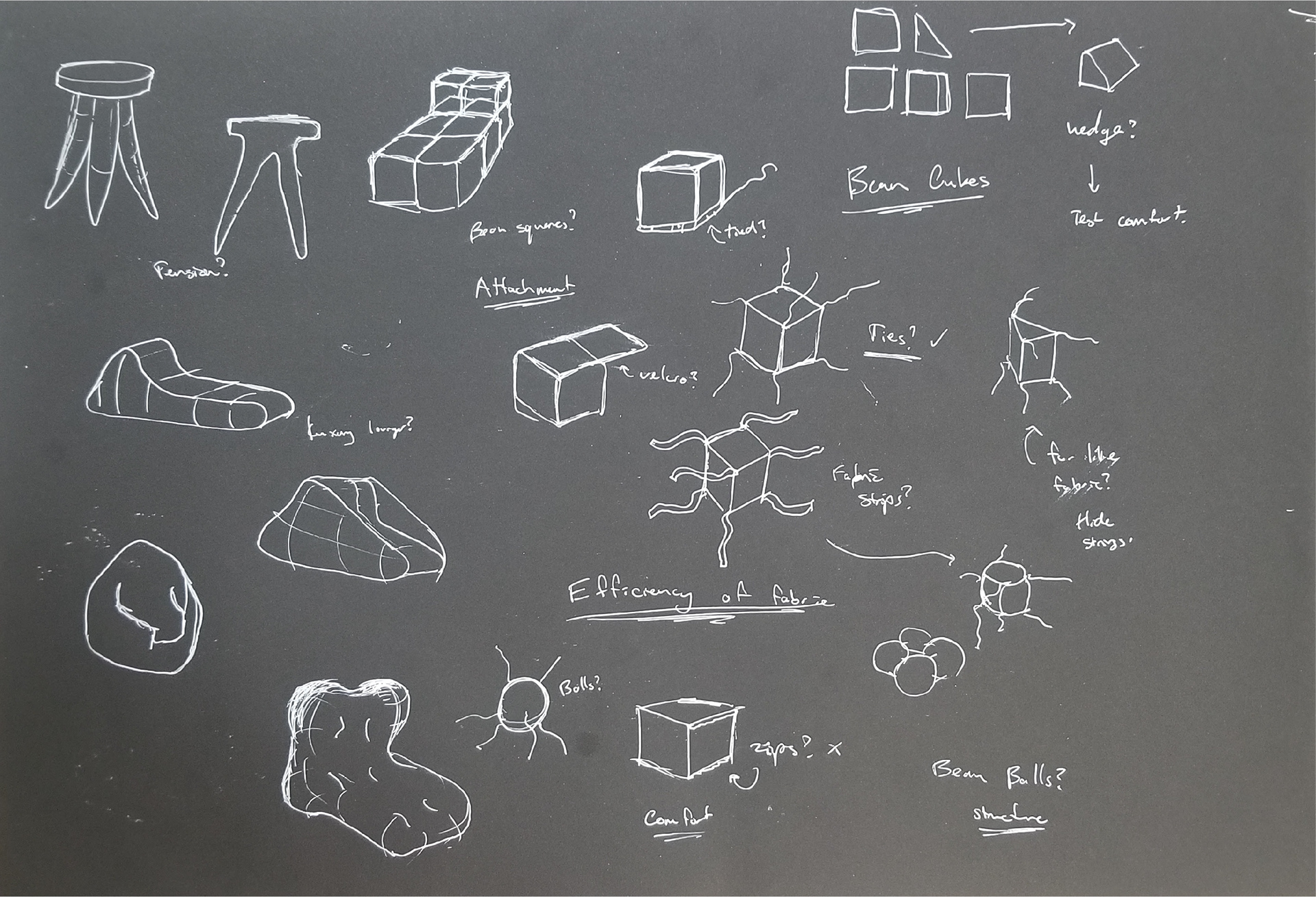

To start this project I created some simple sketch models of lighting and furniture solutions I could create. From personal experience and customer conversations I concluded the customer issues that are outlined below.

"I love L.E.D. strip lights but they are ugly and unruly." From this emotional customer comment I created the rope light below. Using suction cups to attach to walls this lighting fixture can be easily adjusted to a students changing needs. Could be easily created and manufactured on a C.N.C. lathe.

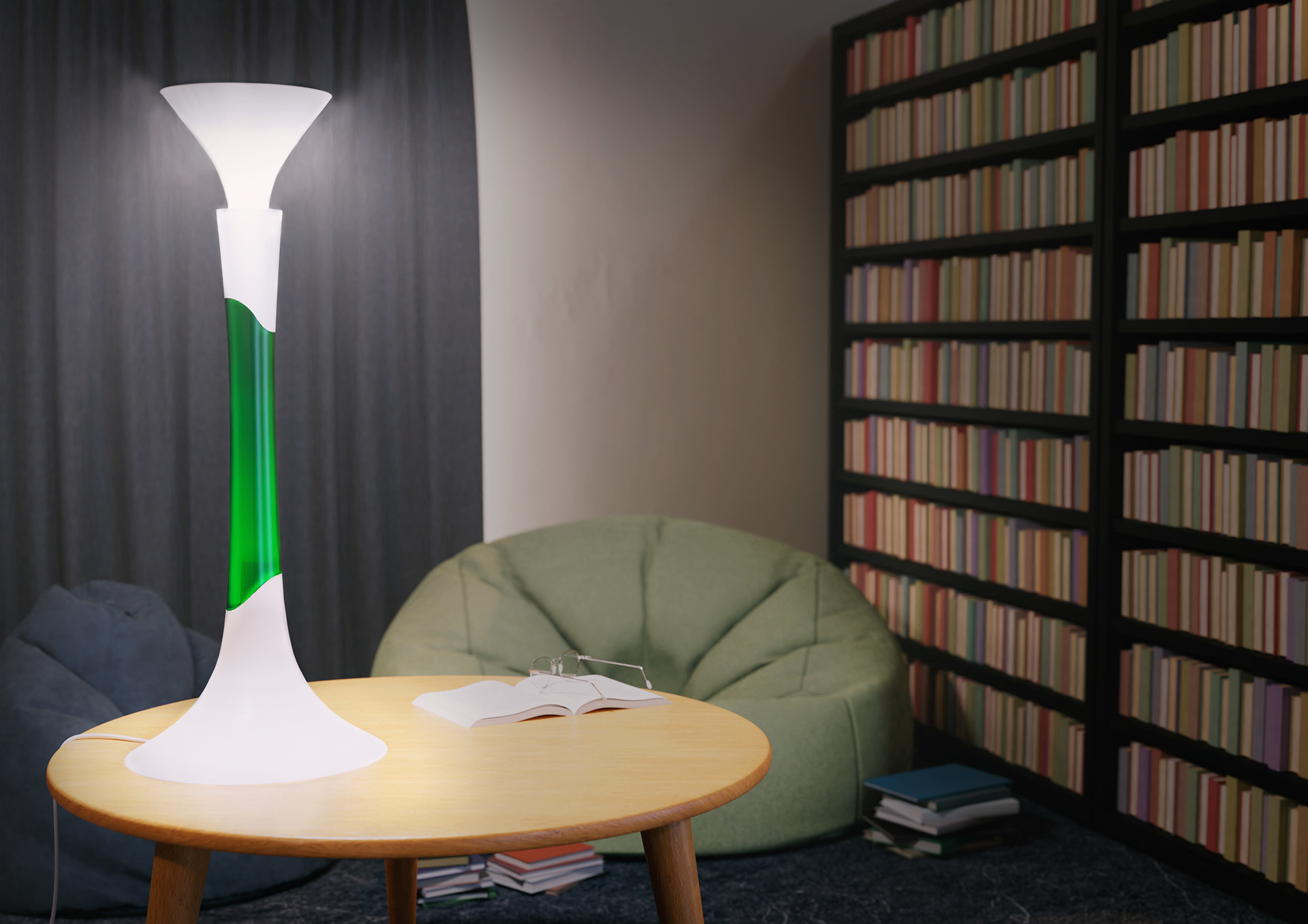

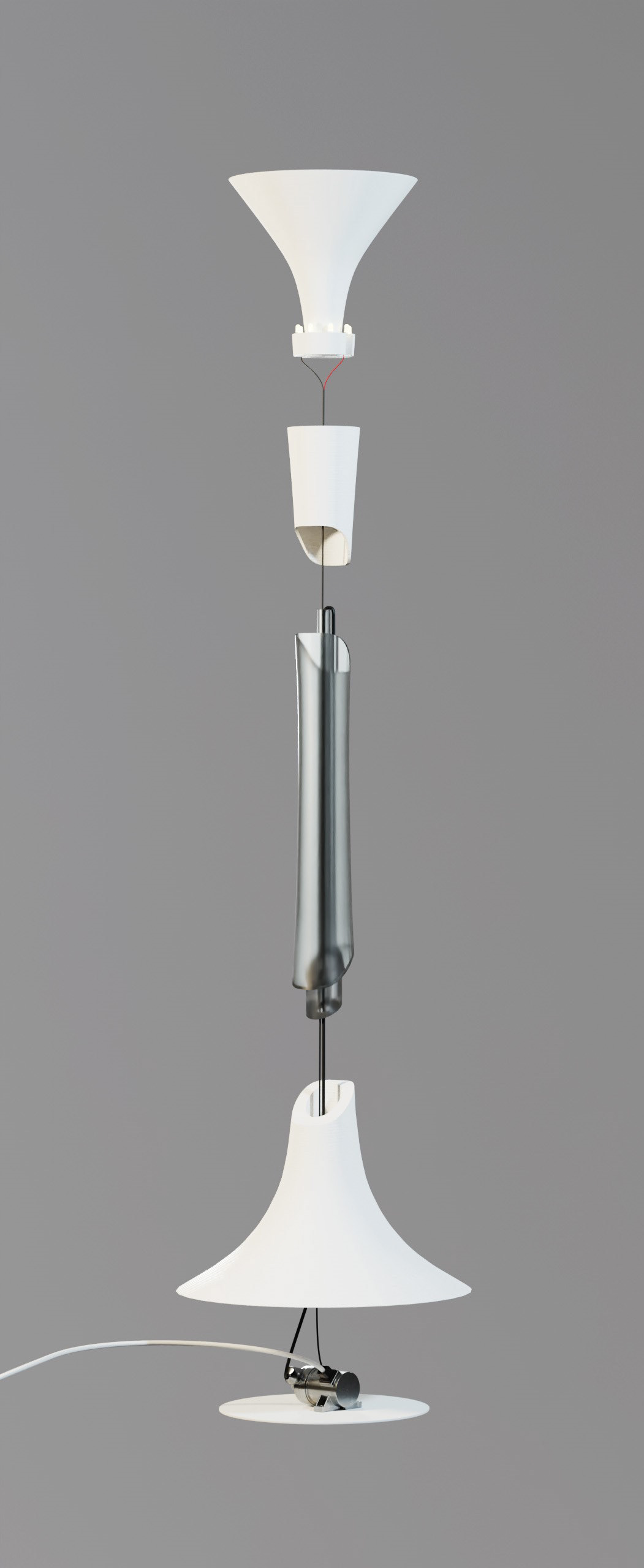

"We love having plants in the flat to keep the air fresh, but we're so bad at keeping them alive." From this customer comment, I generated a lamp that contains a tube of chlorella algae, when air is bubbled through it, it would reoxygenate the air. This has only a fraction of maintenance comparative to a plant and converts significantly more carbon dioxide to oxygen.

After more customer conversations, a new issue was highlighted more significantly than the others, prompting an idea pivot. "Couches are so damn expensive, we keep buying second hand couches that don't fit our flat well." "The only furniture we've bought new is a bean bag, 'cause they're cheap."

After this comment from multiple customers, I concluded that a combination of the cheap manufacturing process behind bean bags could be implemented into a chair or couch.

After experimenting with a stool that could be supported by the tension of the filling of beans, I deemed this design unfit for the market. Students want a communal style of living and seating that will match this.

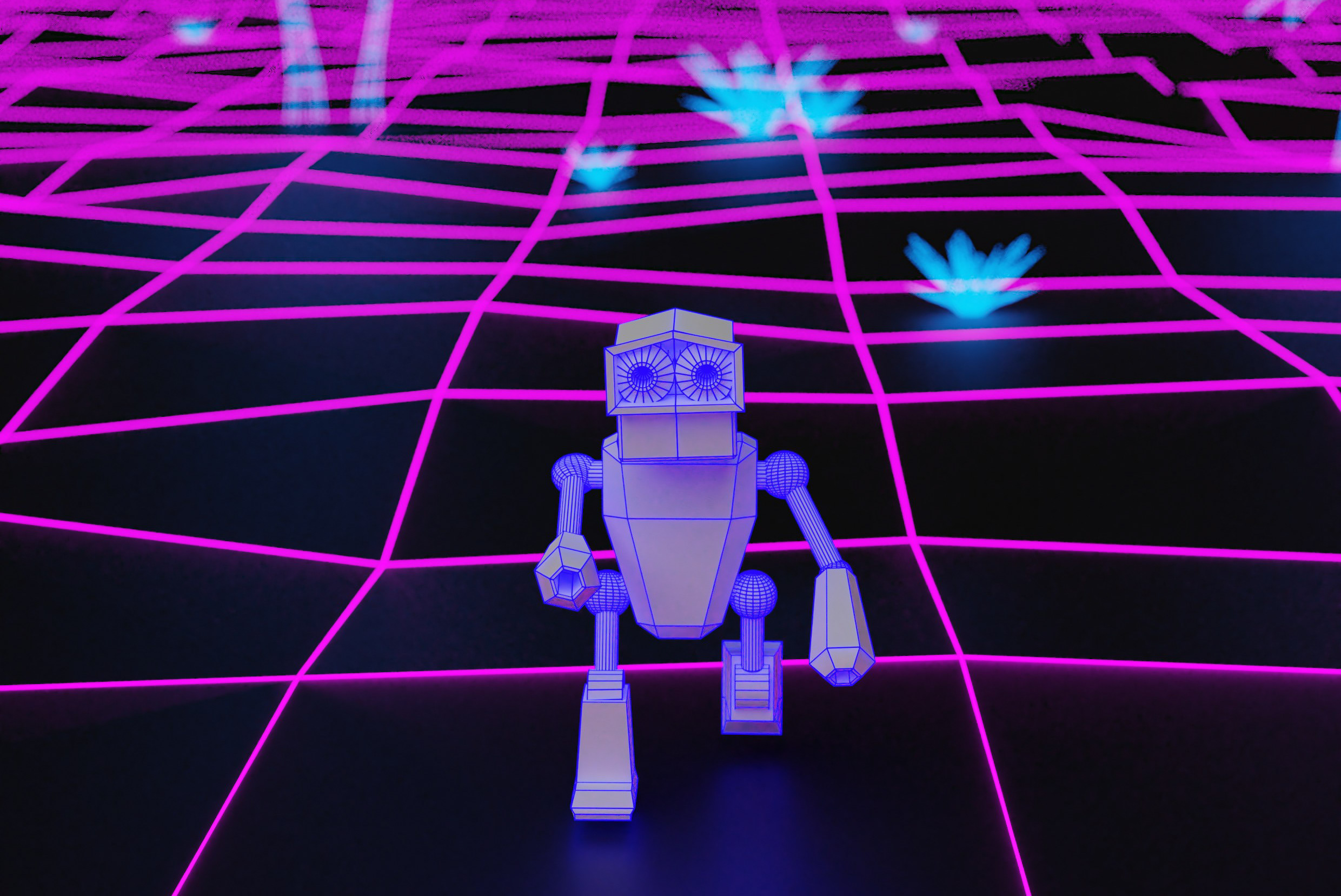

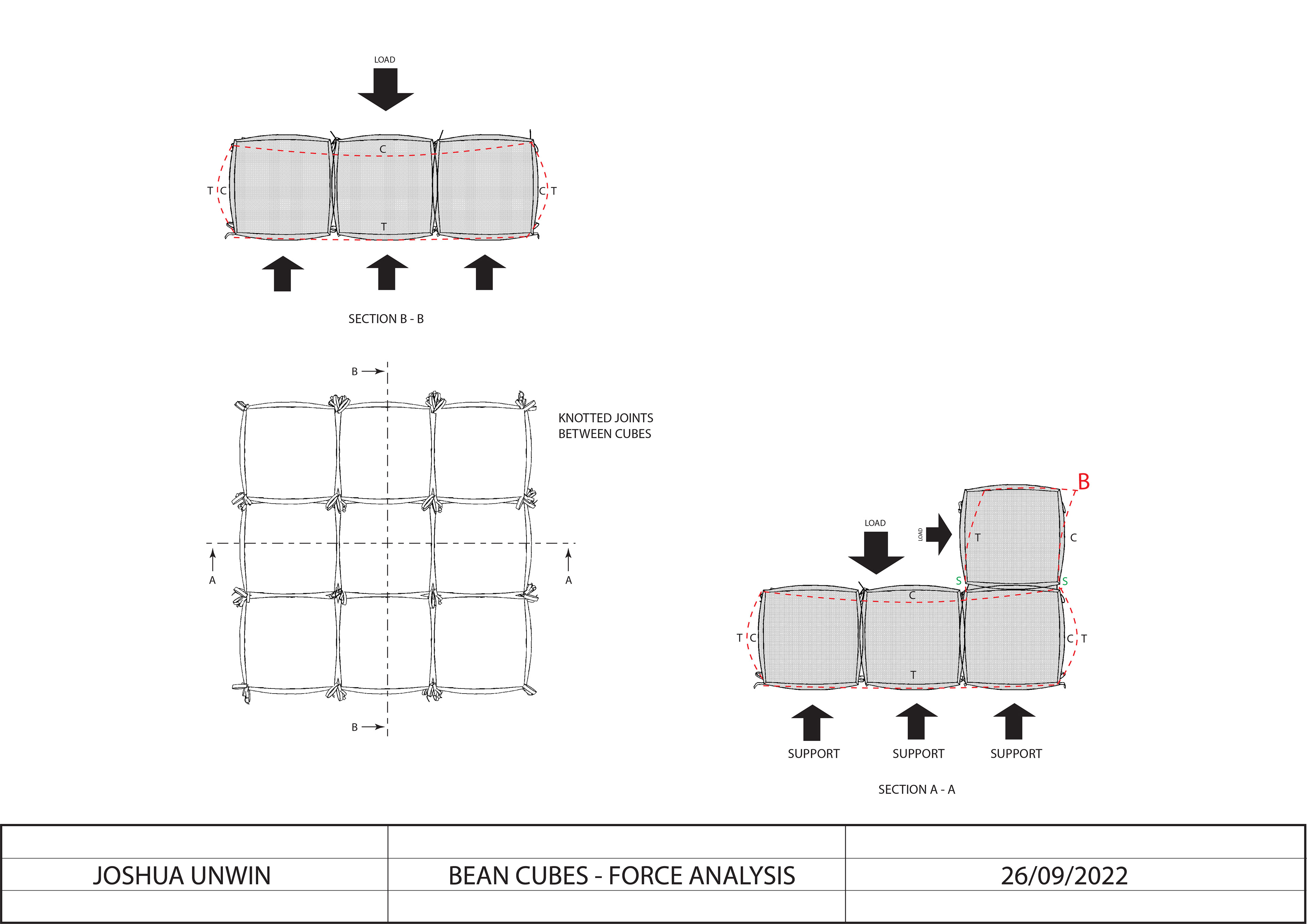

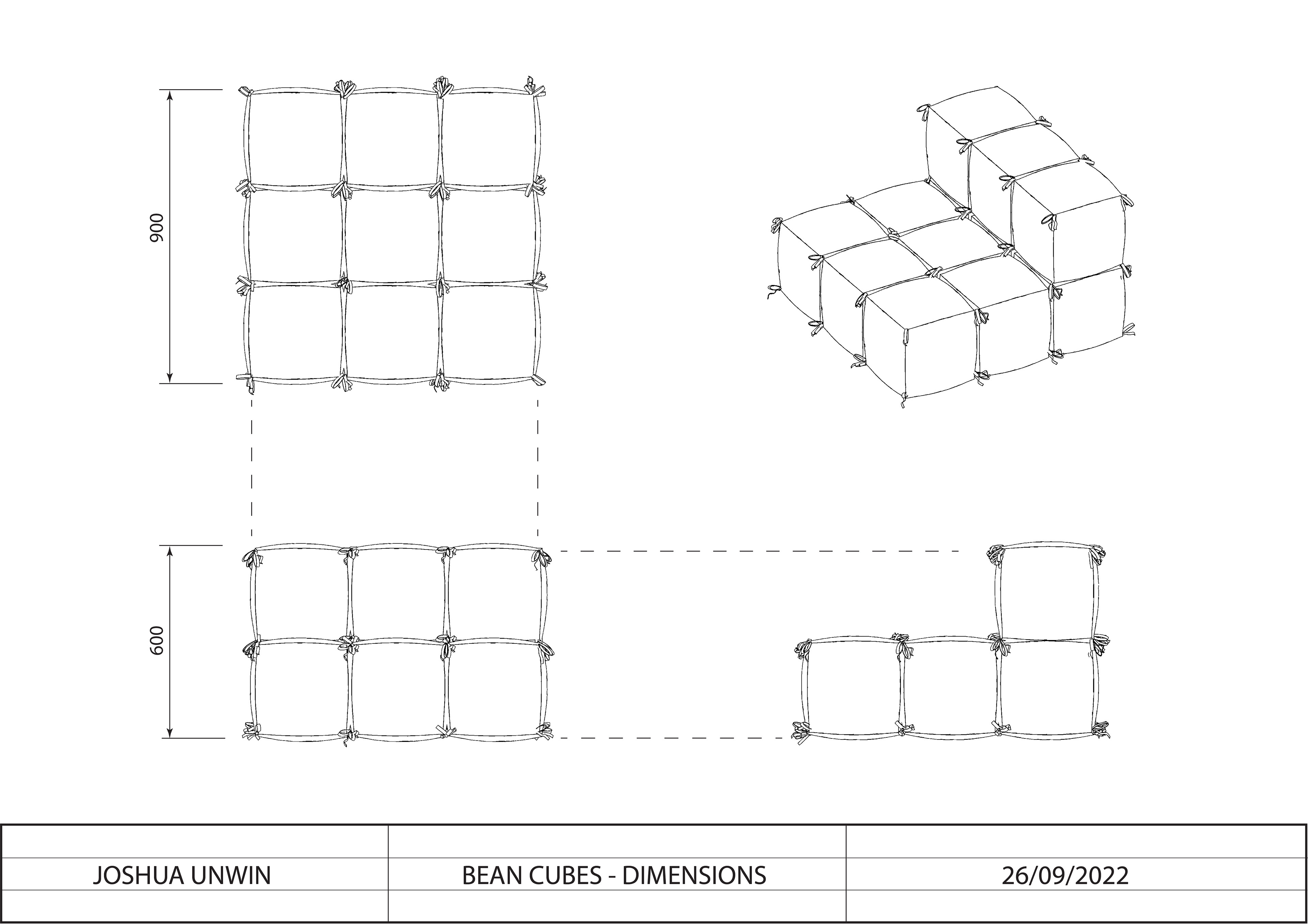

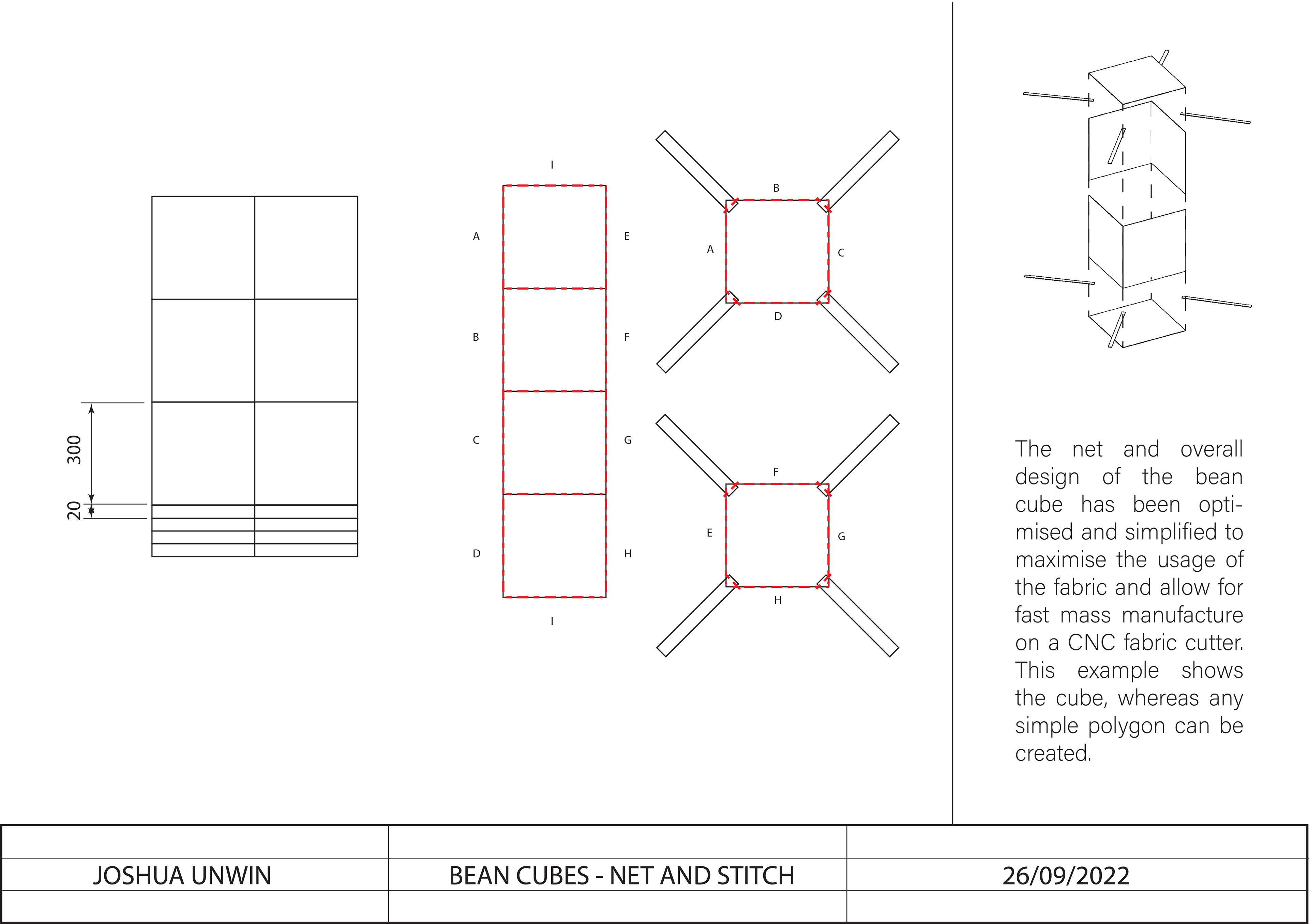

The final iteration is a furniture system that consists of shapes filled with foam beans that can be tied together to form any shape the customer needs.

The final model was stitched together from faux mink material stuffed with bean bag beans. The tight stuffing of the shapes provides ample support, whilst maintaining comfort